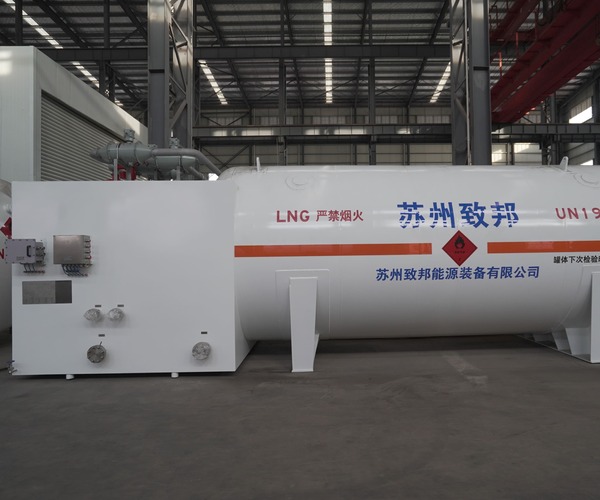

ASME "U" &"T" Stamp Certified Cryogenic Tanks Manufacture

2-200m³, For LOX, LIN, LAR LIN, LCO2; One-stop service;

The Wonderful Products That We Are Making

We provide one-stop service from design, production, shipment, and certificate of origin delivery.

Visit Our Workshop

- This workshop is 49,000㎡, 25 meters high, and 30 meters wide.

- We focus on designing and producing cryogenic tanks, micro bulk, ISO tanks, LNG fueling stations, fuel gas supply systems, and cryogenic vaporizers, among other products.

- The volumes range from 2 to 200 m³ and are suitable for LOX, LIN, LAR, LCO2, and LNG.

- Welcome to our YOUTUBE channel to visit all the production workshops.

Tip: Choose 1080p playback for an enhanced viewing experience.

Factory Certification

- A2, C2, C3, B4(1)(2) pressure vessel manufacturing license;

- A1, A2, C2, C3 design license;

- ASME “U” steel seal authorization certificate;

- CCS classification society factory;

- ISO9001 quality system certification;

- ISO14000 environmental protection system certification.

- What is the ASME “U” Stamp?

Our Clients

- We have deep cooperation with clients in South Korea, Japan, Malaysia, Thailand, and Russia in the ISO tank container business.

- Having a large market share in China’s LNG power ship reconstruction and LNG bunkering system, Cooperating with CNPC, China Gas, ENN Gas, etc;

- We are gradually developing the business of cryogenic tanks and gas supply systems in overseas markets.

- Please Contact us and join us!

FAQ

Most requested questions from our clients, and the answers. If you have other questions or need any support, please feel free to contact our team.

The warranty term is one year. The design life is 20 years.

We will provide free technical guidance during the service life and the best price for repair spare parts.

Usually, we will provide the factory’s quality inspection report and the report from the National Pressure Vessel Design and Testing Institute.

In addition, if cryogenic tanks are used on ships, you can also invite the classification society to issue a third-party test report. The cryogenic tank of a fuel gas supply system usually needs the above report.

The shipment container size primarily determines it.

If any of the dimensions of the container length, width, and height are exceeded, we must use frame cabinets.

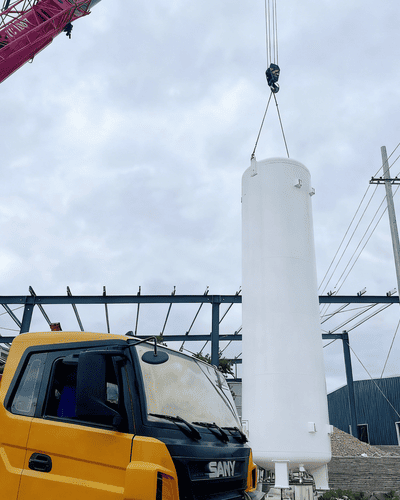

Due to our design, standing transport is essential for microbulk tanks. Because they are higher than the container, they are typically transported using an open-top container.

Our freight forwarders are experienced, and we are happy to provide one-stop service.

Steel is the most used material, so the prices of cryogenic tanks are heavily influenced by it.

You can also choose stainless steel for microbulk tanks. Stainless steel is usually used in the medical field.

Our production standards are divided into GB and ASME.

GB is the standard of China and is highly accepted in China and Southeast Asia.

ASME, short for the American Society of Mechanical Engineers, is accepted worldwide, but cryogenic tanks below this standard are more expensive.

Yes, we can apply for and provide free-of-charge certificates of origin issued by China Customs or the China Council for the Promotion of International Trade, including CO, FORM A/GSP, FORM E, FORM F, etc.

Yes, OEM is one of our free services. You just need to provide the logo’s artwork file.

Self-owned Workshop

We own our workshops and save about $800,000 a year in rent. That would be a cost reduction of about $2,000 per unit.

Experienced Staffs

Most ngineers and workers are from the top cryogenic storage tank manufacturers, such as Charter, Hang Oxygen, Jiang Oxygen, CIMC, etc.

100% Inspection of Weld Seam

Each weld seam was inspected using X-rays, and the quality engineer confirmed no cracks, bubbles or impurities.

Third Party Detection

Third-party (CCS, ABS, BV, DNV, etc.) testing or testing by customer engineers is welcome.

One Stop Service

One-stop service covering the design, production and transportation of cryogenic tanks. Save your time and costs.

Digital Managment

The digital liquid level gauge replaces the traditional liquid level gauge and uses a SIM card to transmit the liquefied gas information to the mobile phone APP. One mobile phone can manage hundreds of cryogenic tanks. Super friendly to gas suppliers.

Supply Chain Advantages

We supply cryogenic tanks to the global market, including China, with an annual output of over 1,000 sets. Our vast production capacity enables us to purchase large quantities when steel prices are low and gives us a price advantage when purchasing valves and meters.

Free Certificates of Origin

We offer various certificates of origin for free and quickly. The correct certificates of origin can reduce import tariffs and make your business more competitive.

Projects

We’d love to hear from you!Please send us a message using the form now. We will contact you within one working day. Please pay attention to the email with the suffix “@wingomarine.com.”