Micro Bulk Tanks

We have a professional workshop to produce micro bulks from 3m³ to 10m³. The delivery time is only around 2 weeks. Don’t hesitate to contact us at any time.

- Due to the new process and excellent multi-layer insulation material, low static vaporization rate, stable insulation performance, and little gas consumption are realized.

- A vacuum regeneration chamber is set at both the entrance and exit to ensure a long-term lifetime and stable performance of the vacuum inter-layer.

- The use of a locating pin for the internal container avoids shifts caused by outside forces, upgrading the reliability of the whole structure.

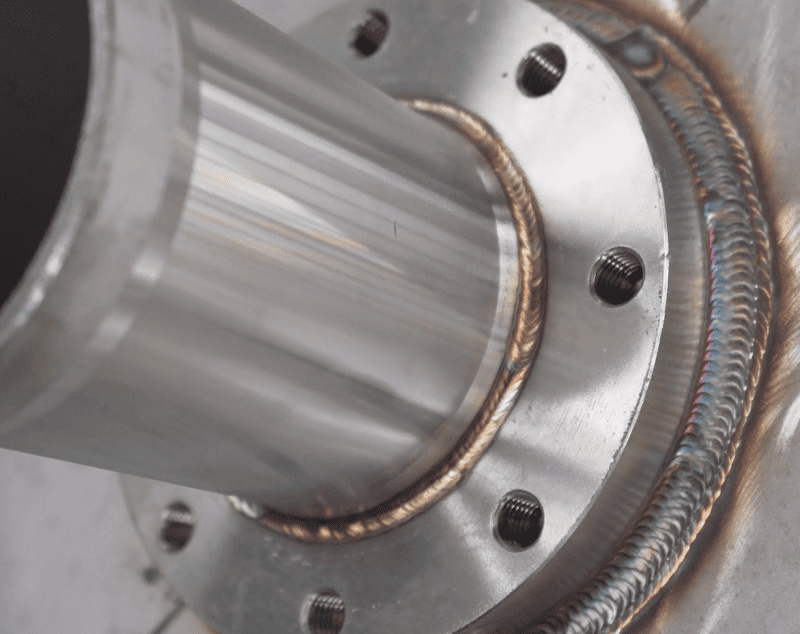

- Compact structure: all pipelines are guided from the top distributor. The connection of pipes is welded but not screwed to reduce the possibility of medium leakage and upgrade safety.

- “Worcester”ball valve and “Generant” check valve are used on the filling interface. So, a transport truck and automatic liquid filling truck can be used to fill the tank directly and realize O wastage.

- The micro bulk can be placed on the ground directly without any foundation, taking only a little space. It can also be safely and quickly moved by lifting a lug on the top or a forklift pallet on the bottom.

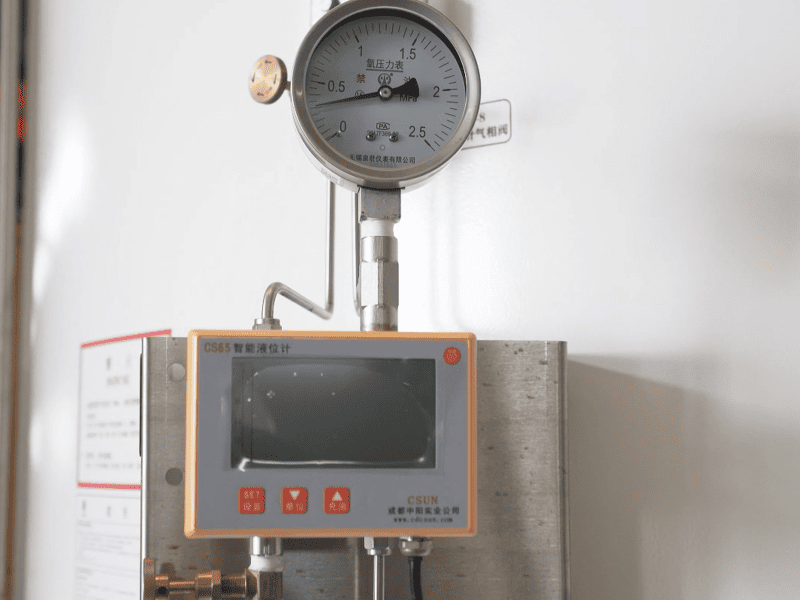

- Digital liquid-level gauges can be installed. Multiple units of micro bulks can be managed simultaneously through a mobile phone APP. The remaining liquefied gas capacity can be checked at any time, and replenishment can be done quickly and accurately.

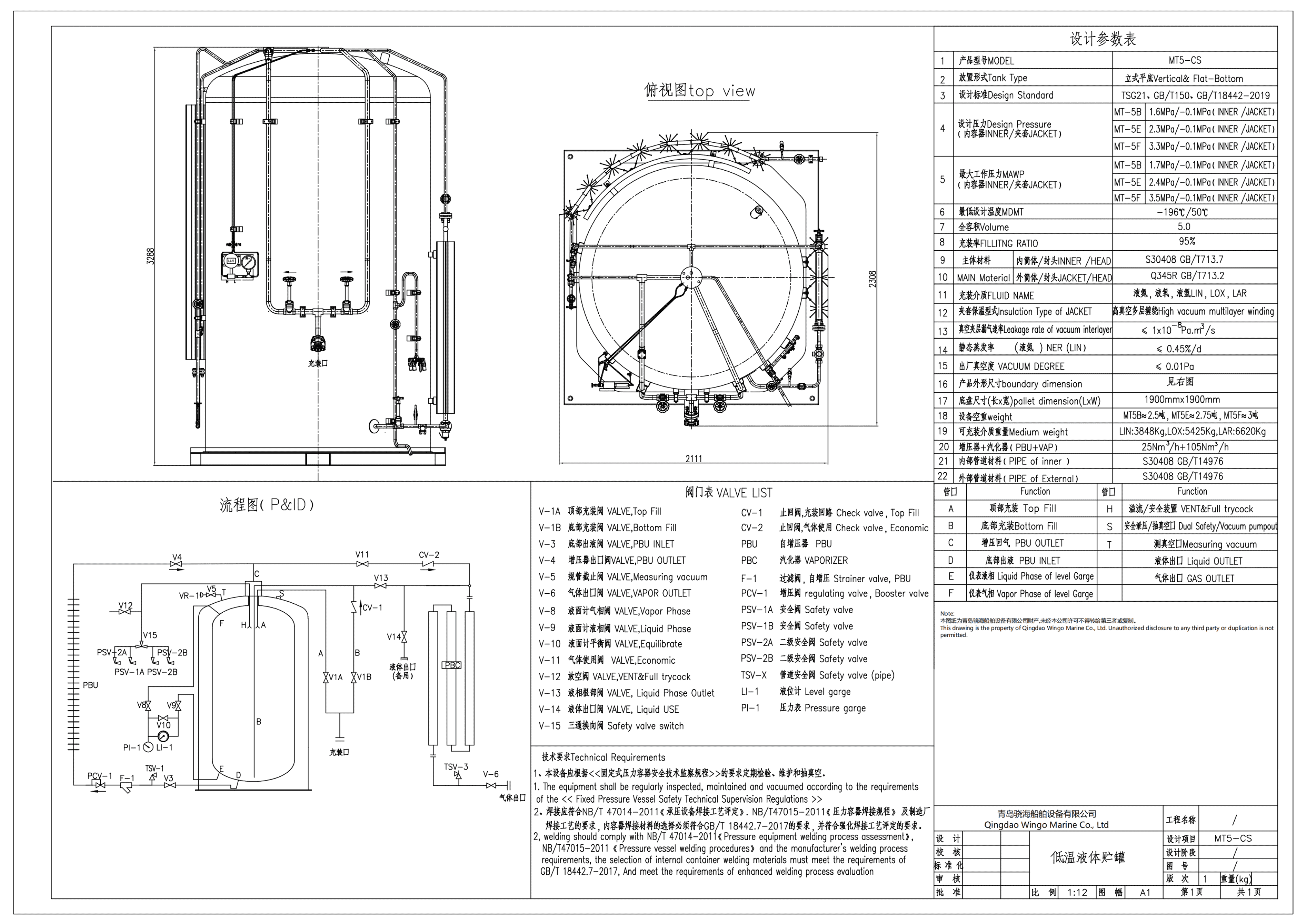

Technical Specification of Micro Bulk Tanks

| Model Number | MT300 | MT500 | MT7500 | MT10000LP | |||

|---|---|---|---|---|---|---|---|

| Type | Vertical & flat bottom | ||||||

| Design Code | TSG21, GB/T150, GB/T18442-2019 | ||||||

| Design Pressure | 3000MP | 5000MP | 7500MP | 1.0Mpa/-0.1Mpa | |||

| (Inner vessel/outer shell) | 1.6Mpa/-0.1Mpa | 1.6Mpa/-0.1Mpa | 1.6Mpa/-0.1Mpa | ||||

| 3000HP | 5000HP | 7500HP | |||||

| 2.3Mpa/-0.1Mpa | 2.3Mpa/-0.1Mpa | 2.4Mpa/-0.1Mpa | |||||

| 3000VHP | 5000VHP | 7500VHP | |||||

| 3.3Mpa/-0.1Mpa | 3.3Mpa/-0.1Mpa | 3.5Mpa/-0.1Mpa | |||||

| Max Working Pressure | 3000MP | 5000MP | 7500MP | 1.0Mpa/-0.1Mpa | |||

| (Inner vessel/outer shell) | 1.6Mpa/-0.1Mpa | 1.6Mpa/-0.1Mpa | 1.6Mpa/-0.1Mpa | ||||

| 3000HP | 5000HP | 7500HP | |||||

| 2.3Mpa/-0.1Mpa | 2.3Mpa/-0.1Mpa | 2.3Mpa/-0.1Mpa | |||||

| 3000VHP | 5000VHP | 7500VHP | |||||

| 3.3Mpa/-0.1Mpa | 3.3Mpa/-0.1Mpa | 3.3Mpa/-0.1Mpa | |||||

| Design Temperature | -196℃ / 50℃ | ||||||

| (Inner vessel/outer shell) | |||||||

| Full Volume | 3.0m³ | 4.99m³ | 7.5m³ | 9.89m³ | |||

| Filling Rate | 95% | ||||||

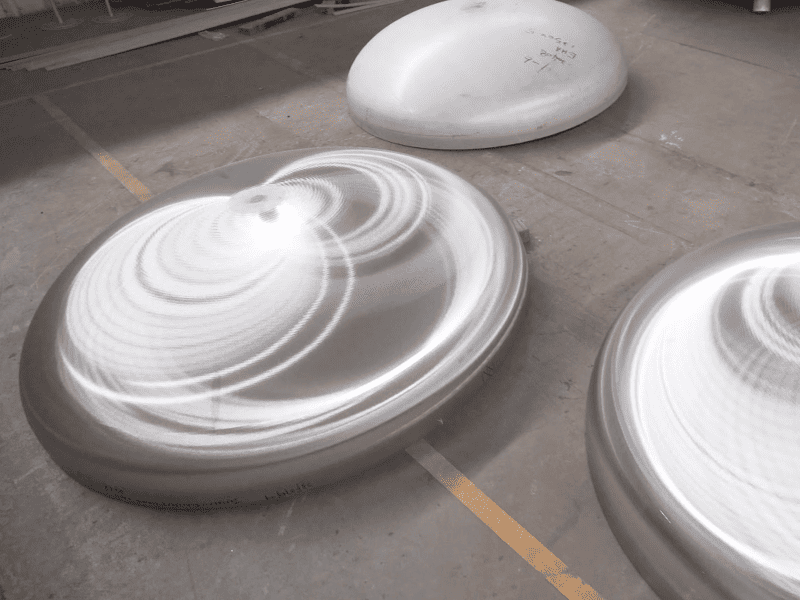

| Main Body Material | Inner vessel/sealing head: S30408 GB/T24511 | ||||||

| Outer shell/sealing head: Q345R GB/T713 | |||||||

| Filling Medium | LO2, LN2, LAr | ||||||

| Interlayer Medium | High vacuum multilayer insulation | ||||||

| Helium Leak Test | Yes | ||||||

| Vacuum Interlayer Leakage and Outgassing Rate | ≤1×10-6 Pa.m3/s | ≤1×10-8 Pa.m3/s | |||||

| Static Evaporation Rate | ≤0.66/d | ≤0.45/d | ≤0.40/d | ≤0.22/d | |||

| (Liquid Nitrogen) | |||||||

| Packing Pressure of inner vessel when leaving factory | 20KPa | ||||||

| Factory Vacuum | ≤0.01Pa | ||||||

| Paint Brand, Film Thickness | JUTON 200um | ||||||

| Support Form | Hang Ceiling | ||||||

| Dimensions(L*W*H) mm | 2005*1872*3090 | 2140*2260*3360 | 2800*2780*3380 | 2887*2795*3330 | |||

| Chassis Size(L*W)mm | 1800*1800mm | 2000*2000mm | 2450*2450mm | 2550*2550mm | |||

| Empty Weight | 3000MP: 1890kgs; | 5000MP: 2786kgs; | 7500MP: 3390kgs; | 4272kg | |||

| (Including Chassis) | 3000HP: 2058kgs; | 5000HP: 3100kgs; | 7500HP: 3910kgs; | ||||

| 3000VHP: 2346kgs; | 5000VHP: 3560kgs; | 7500VHP: 4575kgs; | |||||

| Internal Piping Material | Stainless steel S30408 GB/T14976 | ||||||

| External Piping Material | Stainless steel S30408 GB/T14976 | ||||||

| Pressure Booster | 25Nm3/h | 25Nm3/h | 45Nm3/h | 25Nm3/h | |||

| Vaporizer | 75Nm3/h | 105Nm3/h | 150Nm3/h | 200Nm3/h | |||

| LOGO | According to customer’s requirements | ||||||

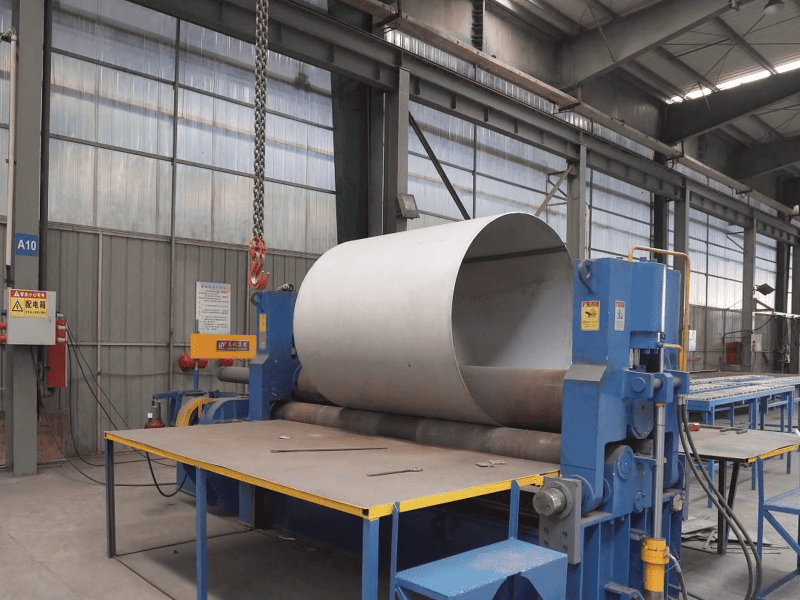

Self-owned Workshop

We own our workshops and save about $800,000 a year in rent. That would be a cost reduction of about $2,000 per unit.

Experienced Staffs

Most ngineers and workers are from the top cryogenic storage tank manufacturers, such as Charter, Hang Oxygen, Jiang Oxygen, CIMC, etc.

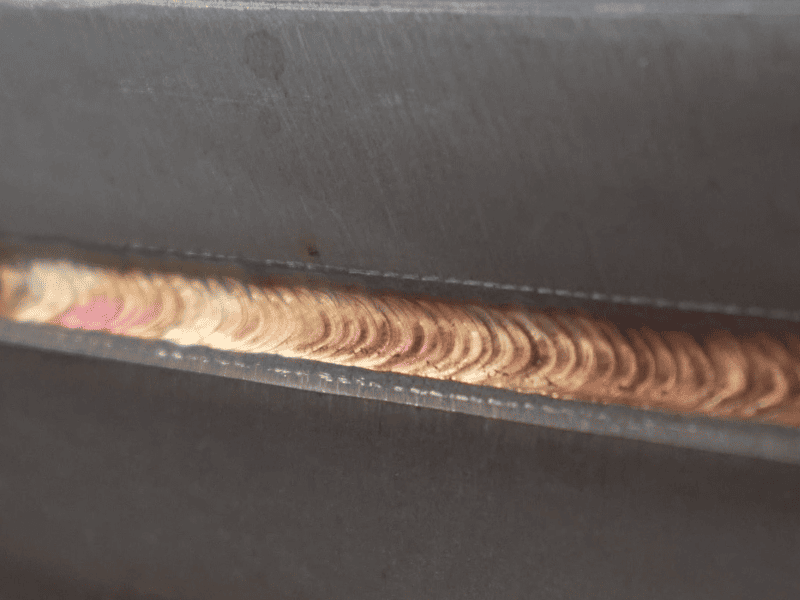

100% Inspection of Weld Seam

Each weld seam was inspected using X-rays, and the quality engineer confirmed no cracks, bubbles or impurities.

Third Party Detection

Third-party (CCS, ABS, BV, DNV, etc.) testing or testing by customer engineers is welcome.

One Stop Service

One-stop service covering the design, production and transportation of cryogenic tanks. Save your time and costs.

Digital Managment

The digital liquid level gauge replaces the traditional liquid level gauge and uses a SIM card to transmit the liquefied gas information to the mobile phone APP. One mobile phone can manage hundreds of cryogenic tanks. Super friendly to gas suppliers.

Supply Chain Advantages

We supply cryogenic tanks to the global market, including China, with an annual output of over 1,000 sets. Our vast production capacity enables us to purchase large quantities when steel prices are low and gives us a price advantage when purchasing valves and meters.

Free Certificates of Origin

We offer various certificates of origin for free and quickly. The correct certificates of origin can reduce import tariffs and make your business more competitive.

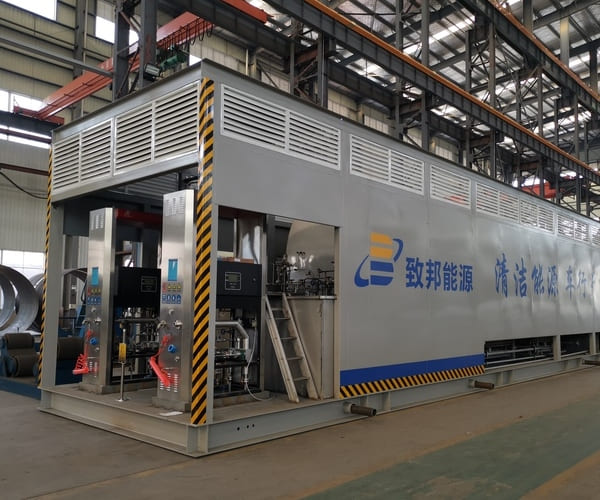

Projects

The warranty term is one year. The design life is twenty years.

We provide free technical guidance during the service life and the best price for the repair of spare parts.

Depending on the size of the cryogenic tank, flat rack containers or open-top containers will be used.

We have professional loading workers, drivers, and freight forwarders who can provide one-stop service. Click to learn more.

Yes, we can apply for and provide free-of-charge certificates of origin issued by China Customs or the China Council for the Promotion of International Trade, including CO, FORM A/GSP, FORM E, FORM F, etc. Please click to learn more.

We support EXW, FOB, CIF, etc. Let us talk about your needs and make the most suitable price terms.

We support T/T, sight L/C, cash, West Union, Monygram, etc. Please click to learn more.

Related Products

Send Your Inquiry Today

Our senior sales engineer Tony or his assistant Miss Eva will reply to your email within 12 hours.

Please note the email with “@wingomarine.com”.

- ctsales@wingomarine.com

- 0086 18562793835(whatsapp)

- 0086 0532 87037615

- No. 30 Lehong Road, Leyu Town, Zhangjiagang City, Jiangsu, China