LNG Bunkering Barge

LNG bunkering barge provides LNG fueling services for ships that have replaced their LNG fuel gas supply systems. If you need it, please feel free to contact us.

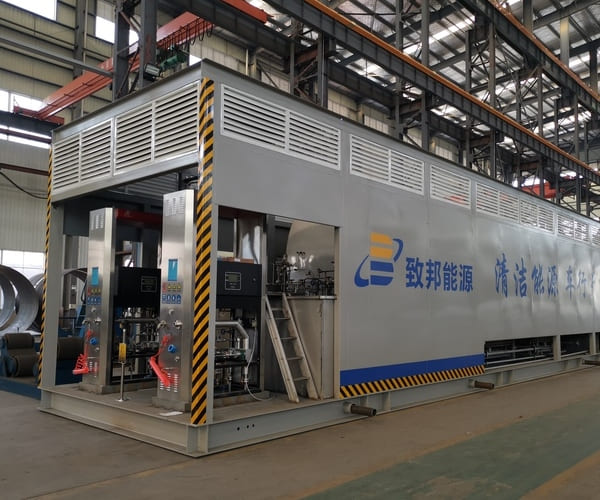

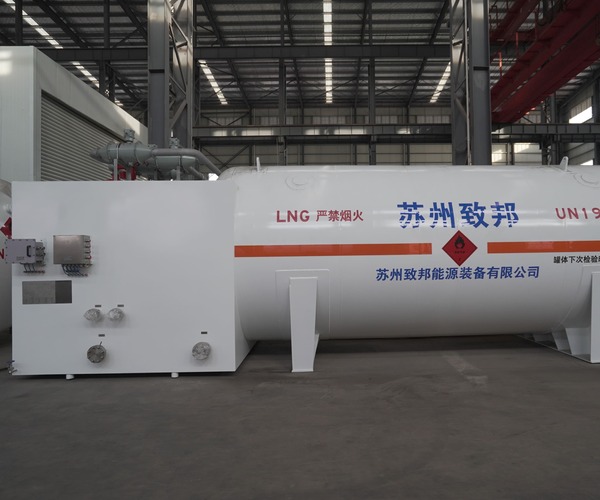

The LNG Bunkering Barge is a floating refueling station designed to deliver LNG fuel to vessels at port hubs or navigational nodes. Unlike land-based stations, it provides superior siting adaptability and faster commissioning, making it ideal for inland waterways and coastal shipping networks. We specialize in manufacturing 100-250 m³ LNG storage tanks, essential components of the Bubkering Barge system, which drive the transition toward sustainable maritime operations.

- LNG bunkering barges are a type of barge that arranges the LNG bunkering system on unpowered barges, which are used in inland water areas to refuel other ships with LNG fuel.

- The barge bunkering system’s composition includes cryogenic storage tanks, cold boxes, cryogenic liquid pumps, pressurized vaporizers, buffer tanks, metering devices, bunkering devices (bunkering arms or flexible connection equipment), and electrical control systems.

- The design and production shall comply with the CCS “Specification for Liquefied Natural Gas Fuel Refueling Barges.”

- The main specifications of pontoons include 2*60m³, 2*100m³and 2*250m³.

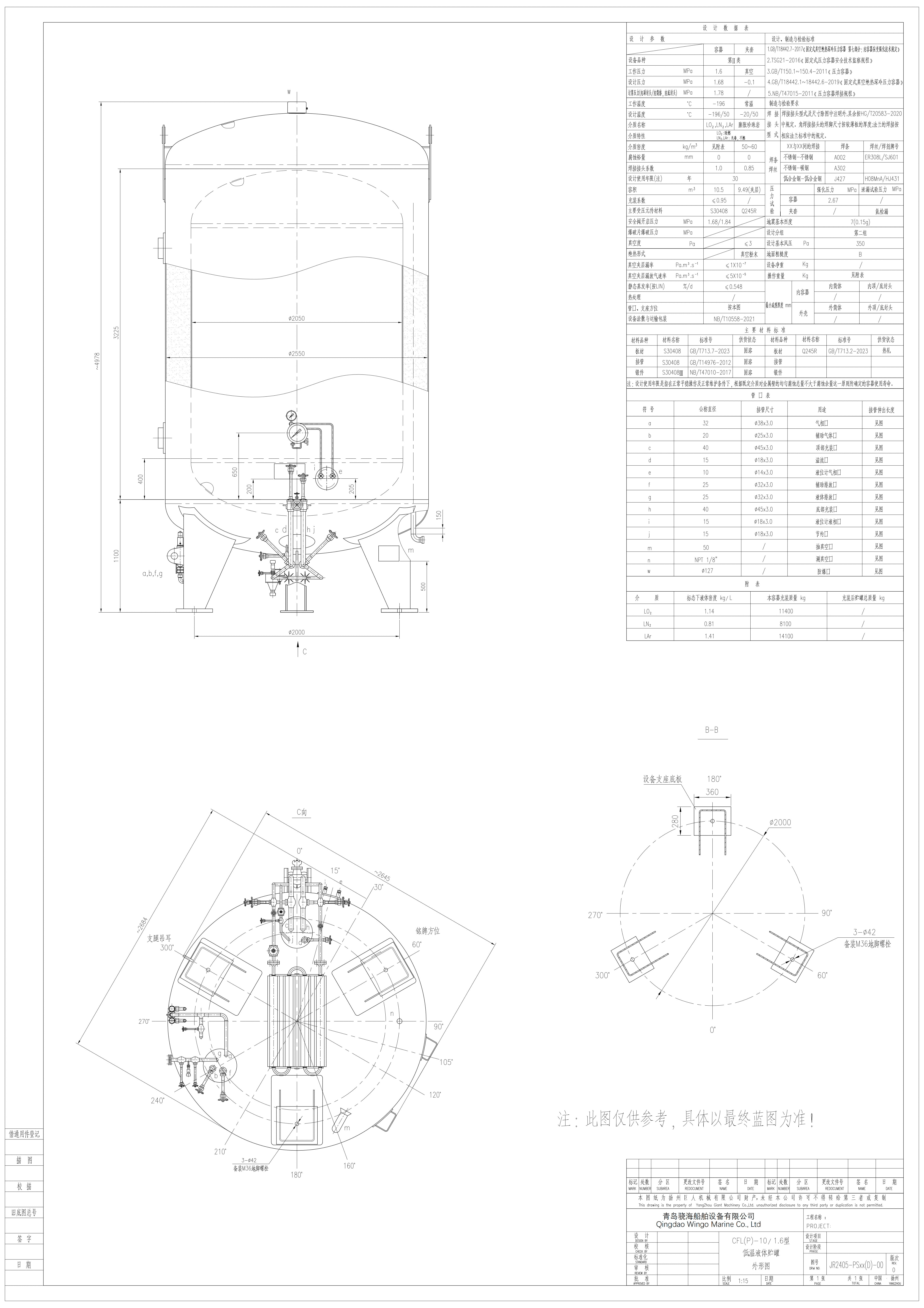

Technical Specification of LNG Bunkering Barge

| Geometric Volume | 100m³ | 150m³ | 200m³ | 250m³ |

|---|---|---|---|---|

| Effective Volume | 90m³ | 135m³ | 180m³ | 225m³ |

| Adiabatic System | High vacuum multi-layer winding insulation | |||

| Design Pressure(MPa) | 1.0/0.1 | |||

| Working pressure(Mpa) | 0.70/Vacuum | |||

| Design Temperature(℃) | -165 | |||

| Working Temperature(℃) | 162/50 | |||

| Sealed-off Vacuum Degree(Pa) | 0.03 | 0.05 | 0.05 | 0.05 |

| Static Evaporation Rate(%/d) | 0.105 | 0.085 | 0.4 | 0.32 |

| Main Vessel Material | S30408 | |||

| Empty Weight(Kgs) | 48000 | 64200 | 80800 | 93300 |

| Total Weight(Kgs) | 88500 | 124900 | 161800 | 194550 |

| Design Code | GB/150-2011, GB/T18842-2019 | |||

Self-owned Workshop

We own our workshops and save about $800,000 a year in rent. That would be a cost reduction of about $2,000 per unit.

Experienced Staffs

Most ngineers and workers are from the top cryogenic storage tank manufacturers, such as Charter, Hang Oxygen, Jiang Oxygen, CIMC, etc.

100% Inspection of Weld Seam

Each weld seam was inspected using X-rays, and the quality engineer confirmed no cracks, bubbles or impurities.

Third Party Detection

Third-party (CCS, ABS, BV, DNV, etc.) testing or testing by customer engineers is welcome.

One Stop Service

One-stop service covering the design, production and transportation of cryogenic tanks. Save your time and costs.

Digital Managment

The digital liquid level gauge replaces the traditional liquid level gauge and uses a SIM card to transmit the liquefied gas information to the mobile phone APP. One mobile phone can manage hundreds of cryogenic tanks. Super friendly to gas suppliers.

Supply Chain Advantages

We supply cryogenic tanks to the global market, including China, with an annual output of over 1,000 sets. Our vast production capacity enables us to purchase large quantities when steel prices are low and gives us a price advantage when purchasing valves and meters.

Free Certificates of Origin

We offer various certificates of origin for free and quickly. The correct certificates of origin can reduce import tariffs and make your business more competitive.

Projects

The warranty term is one year. The design life is twenty years.

We provide free technical guidance during the service life and the best price for the repair of spare parts.

Depending on the size of the cryogenic tank, flat rack containers or open-top containers will be used.

We have professional loading workers, drivers, and freight forwarders who can provide one-stop service. Click to learn more.

Yes, we can apply for and provide free-of-charge certificates of origin issued by China Customs or the China Council for the Promotion of International Trade, including CO, FORM A/GSP, FORM E, FORM F, etc. Please click to learn more.

We support EXW, FOB, CIF, etc. Let us talk about your needs and make the most suitable price terms.

We support T/T, sight L/C, cash, West Union, Monygram, etc. Please click to learn more.

Related Products

Send Your Inquiry Today

Our senior sales engineer Tony or his assistant Miss Eva will reply to your email within 12 hours.

Please note the email with “@wingomarine.com”.

- ctsales@wingomarine.com

- 0086 18562793835(whatsapp)

- 0086 0532 87037615

- No. 30 Lehong Road, Leyu Town, Zhangjiagang City, Jiangsu, China